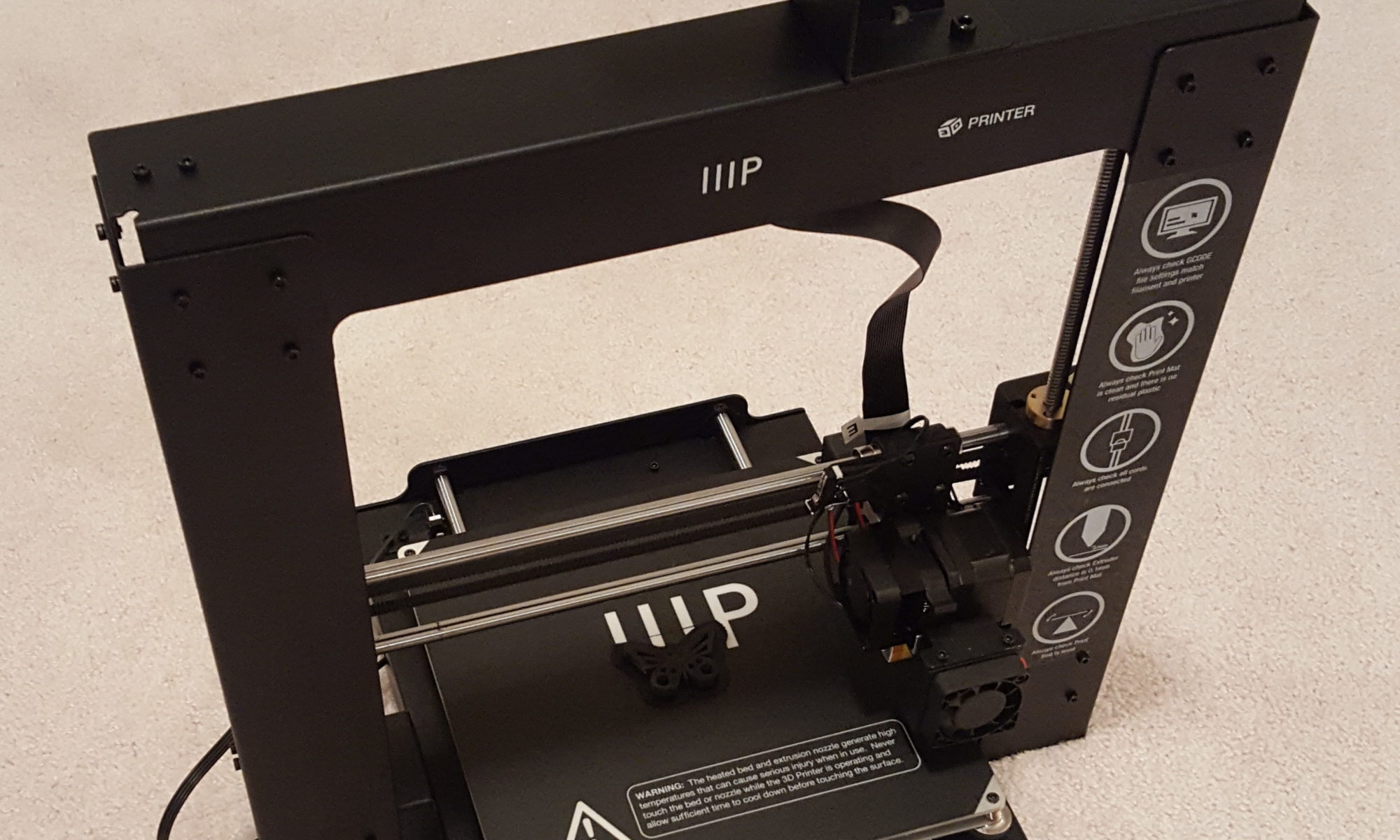

Well now that I’m waiting for the 3D printer I’ve bought to arrive (which ended up being the MP Maker Select Plus, after I discovered a $100 discount code to bring the price down to $300), I thought I’d start looking at the available filament options. From the ordering website, the potential types available for use include the common options of PLA and ABS, as well as some others I’m less familiar with including XT, Copolyester, PET, TPU, TPC, FPE, PVA, HIPS, Jelly, Foam, and Felty. So what are these, and how do they compare? Well here’s what I’ve found so far.

PLA, polylactic acid, is a thermoplastic that is biodegradable and derived from renewable resources, with corn starch being a common starting material. PLA is normally extruded around 160°C-220°C, doesn’t require a heated printbed but benefits from a 60°C temperature, remains soft around 50°C, and is fairly slow to cool where it becomes tough but somewhat brittle. It can be sanded and painted, but is difficult to glue. It is described as an easy material to work with when starting out, and has a pleasant smell when heated.

ABS, acrylonitrile butadiene styrene, is a petroleum-based thermoplastic. ABS requires hotter temperatures when printing, around 210°C-250°C, and requires a heated printbed to prevent warping of the print. It can be easily sanded and glued, but can produce some mild but unpleasant fumes and benefits from printing in a ventilated area.

Here are some quick one liners of the other printing materials. XT is a variety of copolyster in the Amphora™ produced by the Eastman Chemical Company in conjunction with colorFabb with low odor and improved strength. Copolyester results from modifying polyesters by introducing certain diacids or diols, and includes the Amphora and XT lines. PET, polyethylene terephthalate, is a commonly used plastic, and the glycol modified PETG is described as more flexible and durable than PLA while being easier to print than ABS, but is absorbs moisture from the air and is sticky during printing. TPU, thermoplastic polyurethane, is elastic but slightly rigid with rubber-like qualities. TPC, thermoplastic copolyester, is another elastomer with more resistance to temperature and chemical exposure. FPE, flexible polyster, is a filament with a combination of rigid and soft polymers and is comparable but softer and more flexible than PLA. PVA, polyvinyl alcohol, is a water-soluble plastic used for providing a removable support structure to a print with overhangs. HIPS, high impact polystyrene, is a copolymer with good hardness and flexibility, and serves as a good support material as it can be easily removed with limonene. Jelly, foam, and felty filaments start out with two materials, one of which that is soluble and when removed leaves the remaining material with porous structures, which provide unique properties and textures to the finished product.

In the future, I’ll take a deeper look at some of the filaments I intend to use with my prints, including a few others I have yet to look into like wood, metal, carbon fiber, conductive, wax, and ceramic materials.

References:

Monoprice Maker Select Plus 3D Printer

What Material Should I Use For 3D Printing?

Amphora May Revolutionize 3D Printed Plastics

The Ultimate Filament Guide, 3D Printer Filament – 25 Best Types & Comparison Charts

Kai Parthy Gets Felty, Foamy and Porous with PORO-LAY Line of Filaments

Foamy, Felty, Porous & Coconut Wood?